热门关键词:济南彩钢板 | 济南复合板 | 济南彩钢瓦 | 济南c型钢 | 济南钢结构 |

新闻中心

联系我们

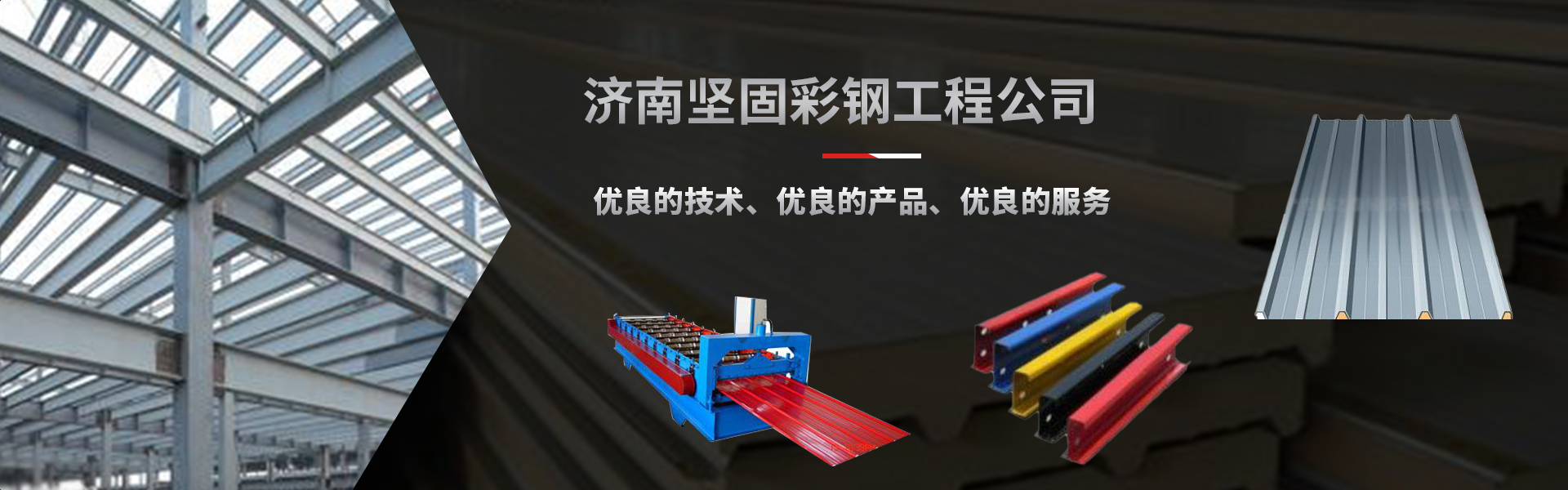

济南坚固彩钢工程公司

联系人:孙经理

电话:18963458998

地址:济南市工业北路81号北邻

如何保证压制的C型钢不厚均匀?

来源:http://www.jnjgcg.com/ 日期:2021-04-22 发布人:

不同用户,对于C型钢壁的厚度要求也是不同的,有的会比较后,有些却是非常的薄。如果要同时满足这些要求的话,所选用的C型钢生产工艺和设备非常关键。据小编所知,一般了冷轧方式是难以生产出高品质的C型钢,因此得用C型钢机来完成。

Different users have different requirements for the thickness of C-section steel wall. Some will be compared, but some are very thin. If we want to meet these requirements at the same time, the selected C-beam production process and equipment is very critical. As far as Xiaobian knows, it is difficult to produce high quality C-beam by cold rolling, so it has to be finished by C-beam machine.

材料从C型钢机的尾部进入之后,经过各种压辊的压制,从头部输出成型后的C型钢。这不仅使得必要的生产加工工艺得到了极大的优化,同时提高了生产下来,还能保证C型钢产品具有均匀的壁厚和复杂的界面形状。

After the material enters from the tail of the C-beam machine, it is pressed by various rollers, and the shaped C-beam is output from the head. This not only makes the necessary production process has been greatly optimized, but also improves the production efficiency, and ensures that C-beam products have uniform wall thickness and complex interface shape.

为了达到精确的壁厚,C型钢机在压制C型钢的时候,使用的模具是由一个精准的上模和一些大小规格尺寸相同的下模构成的。在加工之前将它们安装到位,不仅要保证上模与下模能够顺利的,还得确保四周边间隙均匀,这样压制的C型钢才能壁厚均匀。

In order to achieve accurate wall thickness, the mold used by C-beam machine in pressing C-beam is composed of an accurate upper mold and some lower molds with the same size. Before processing, they should be installed in place, not only to ensure the smooth operation of the upper and lower dies, but also to ensure the uniform clearance around the four edges, so that the pressed C-beam can have uniform wall thickness.

下一篇:彩钢瓦厚度有多厚?该如何选择? 上一篇:彩钢瓦各种连接和紧固数量要求

此文关键词: 济南C型钢厂

阅读/ Recommended reading

- 彩钢板房怎么做防火处理? 2024-04-09

- 彩钢复合板施工注意事项 2024-04-07

- 提高彩钢瓦翻新的施工效率方式 2024-03-25

- 彩钢瓦翻新底漆用哪种漆 2024-03-29

彩钢板储存需要注意哪些地方?

[2018-08-23]

彩钢板,尽管在钢板表面有镀锌层和有机涂层的双重保护,但如果长期在潮湿的状态下,表面所积存的水会逐渐渗透通过有机涂层,从而造成有机涂层膜下锌层的腐蚀,因此在储存时必须注意:Alth...