热门关键词:济南彩钢板 | 济南复合板 | 济南彩钢瓦 | 济南c型钢 | 济南钢结构 |

新闻中心

联系我们

济南坚固彩钢工程公司

联系人:孙经理

电话:18963458998

地址:济南市工业北路81号北邻

影响彩钢板质量的几点因素

来源:http://www.jnjgcg.com/ 日期:2021-08-19 发布人:

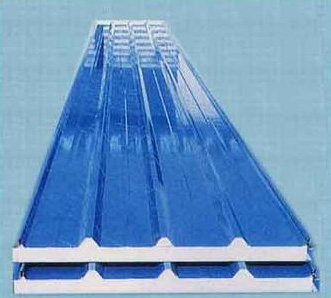

影响彩钢板质量的因素主要体现在基材质量不好、涂层表面张力的改变、前处理不当、固化缺陷、涂装缺陷及划伤等。由冷轧基板生产的彩钢板耐蚀性有限,因为表面涂层的任何细微擦伤都会很快出现红锈影响使用。

The factors affecting the quality of color steel plate are mainly reflected in the poor quality of substrate, the change of coating surface tension, improper pretreatment, curing defects, coating defects and scratches. The color steel plate produced from cold-rolled substrate has limited corrosion resistance, because any slight scratch on the surface coating will soon appear red rust and affect its use.

这种基板的彩色涂层可用于制作家用电器的内部零件,或者用于不高的临时隔离栏,所以彩钢板质量的好坏主要看基板的选择,基板可以采用冷轧基板、电镀锌基板和热镀锌基板、镀铝锌钢板,应根据用途的不同选用合适力学性能的材料。

The color coating of this substrate can be used to make internal parts of household appliances or low temporary isolation bars. Therefore, the quality of color steel plate mainly depends on the selection of substrate. Cold rolled substrate, electro galvanized substrate, hot-dip galvanized substrate and aluminized zinc steel plate can be used as substrates. Materials with appropriate mechanical properties shall be selected according to different purposes.

彩钢板质量的好坏除了和原材料质量的好坏有很大关系外还和生产产品的工艺技术有很大关系,我们在保证原材料一样的前提下要想彩钢板质量好就要保证生产工艺技术。

In addition to the quality of raw materials, the quality of color steel plate is also closely related to the process technology of products. If we want to have a good quality of color steel plate on the premise of ensuring the same raw materials, we must ensure that the production technology is advanced.

脱脂一水洗一表面调整(可选择)一干燥一化学转换膜处理一干燥早期一般都采用喷淋/浸渍法工艺。

Degreasing - washing - surface adjustment (optional) - drying - chemical conversion membrane treatment - drying. Spray / impregnation process is generally used in the early stage.

电镀锌基板的彩钢板,因有锌层保护,耐蚀性比冷轧基板彩色涂层板高,由于锌层薄(一般含锌量为20g/m2)其加工性能比热镀锌好。在制作对耐蚀性有要求的产品和构件时,可考虑选用电镀锌钢板为基板的彩涂板。如空调的内、外构件、洗衣机或冰箱外壳;内装饰用墙壁、家具、照明器材、标牌等。我们都知道彩涂镀锌板颜色是多样的,上色问题、怎样控制彩涂镀锌板不出现色差等都是我们厂家需要克服的问题,也是保证产品质量的关键。

Due to the protection of zinc layer, the corrosion resistance of color steel plate of electro galvanized substrate is higher than that of color coated plate of cold rolled substrate. Due to the thin zinc layer (generally zinc content is 20g / m2), its processability is better than that of hot-dip galvanizing. When making products and components requiring corrosion resistance, the color coated plate with electro galvanized steel plate as the substrate can be considered. Such as the inner and outer components of air conditioner, washing machine or refrigerator shell; Walls, furniture, lighting fixtures, signs, etc. for interior decoration. We all know that the color of color coated galvanized sheet is diverse. The problems of coloring and how to control the color difference of color coated galvanized sheet are all the problems that our manufacturers need to overcome, and they are also the key to ensure product quality.

该工艺除第三步用浸渍法外,其余都用喷淋法施加化学品。在后处理中一般含有铬,通过后处理后不但去除了卷材表面的多余残留物,而且还可在表面生成一层含铬的化合物,提高了卷材的抗腐蚀性能。在铝卷材料应用时,膜重30一65mg/mZ。该工艺的后处理多数也是采用含铬化合物。

In addition to the impregnation method in the third step, the chemicals are applied by spraying method. The post-treatment generally contains chromium. After the post-treatment, not only the excess residue on the surface of the coil is removed, but also a layer of chromium containing compound can be formed on the surface, which improves the corrosion resistance of the coil. When the aluminum coil material is applied, the film weight is 30-65mg / MZ. Most of the post-treatment of this process also uses chromium containing compounds.

下一篇:彩钢板对于防火起作用吗? 上一篇:定制彩钢板需要采取哪些必要的措施

此文关键词: 济南彩钢板

阅读/ Recommended reading

- 彩钢板房怎么做防火处理? 2024-04-09

- 彩钢复合板施工注意事项 2024-04-07

- 提高彩钢瓦翻新的施工效率方式 2024-03-25

- 彩钢瓦翻新底漆用哪种漆 2024-03-29

彩钢板储存需要注意哪些地方?

[2018-08-23]

彩钢板,尽管在钢板表面有镀锌层和有机涂层的双重保护,但如果长期在潮湿的状态下,表面所积存的水会逐渐渗透通过有机涂层,从而造成有机涂层膜下锌层的腐蚀,因此在储存时必须注意:Alth...