热门关键词:济南彩钢板 | 济南复合板 | 济南彩钢瓦 | 济南c型钢 | 济南钢结构 |

新闻中心

联系我们

济南坚固彩钢工程公司

联系人:孙经理

电话:18963458998

地址:济南市工业北路81号北邻

C型钢的制造过程一般采用热轧方式!

来源:http://www.jnjgcg.com/ 日期:2023-04-22 发布人:

C型钢,又称槽钢,是一种具有槽形横截面的钢材,通常用于制作建筑结构、工业设备、桥梁等工程中的构件。其名称来源于其横截面呈现出"C"形。C型钢的规格型号较多,常见的有C100、C125、C160、C200等。C型钢的制造过程一般采用热轧方式,即将钢坯加热一定温度后,在轧机上进行轧制。在轧制过程中,钢坯经过多次轧制压制,终形成具有槽形横截面的C型钢。

C-shaped steel, also known as channel steel, is a type of steel with a channel shaped cross-section, usually used to make components in construction structures, industrial equipment, bridges, and other engineering projects. Its name comes from its cross-section showing a "C" shape. There are many specifications and models of C-shaped steel, including C100, C125, C160, C200, etc. The manufacturing process of C-beam steel generally adopts hot rolling, which means that the steel billet is heated to a certain temperature and then rolled on the rolling mill. During the rolling process, the steel billet undergoes multiple rolling presses to form a C-shaped steel with a groove shaped cross-section.

济南C型钢厂来介绍介绍具体的制造过程,可以概括为以下几个步骤:

Jinan C-beam Steel Factory will introduce the specific manufacturing process, which can be summarized as the following steps:

1.原材料准备。C型钢的原材料是钢坯,需要先对钢坯进行加热处理,使其变得柔软易切割。

1. Preparation of raw materials. The raw material of C-shaped steel is steel billet, which needs to be heated first to make it soft and easy to cut.

2.切割。将加热后的钢坯进行切割,切割出符合标准尺寸要求的坯料。

2. Cutting. Cut the heated steel billets to produce billets that meet the standard size requirements.

3.热轧。将坯料送入热轧机中进行加热和轧制,通过压力将坯料轧制成C型钢的形状。

3. Hot rolling. Feed the billet into the hot rolling mill for heating and rolling, and roll the billet into the shape of C-shaped steel through pressure.

4.整形。将轧制好的C型钢进行冷却和整形,保证其形状和尺寸符合标准要求。5.精整。对整形后的C型钢进行打磨、清洗等处理,使其表面光滑以及符合质量要求。

4. Plastic surgery. Cool and shape the rolled C-shaped steel to ensure that its shape and size meet the standard requirements. 5. Finishing. Grind and clean the reshaped C-shaped steel to ensure its surface is smooth and meets quality requirements.

6.包装。将精整好的C型钢进行包装,保护其表面不被损坏。

6. Packaging. Package the finished C-shaped steel to protect its surface from damage.

通过以上的几个步骤,C型钢就可以被成功制造出来。这种热轧的制造方式可以保证C型钢的强度和韧性,因此被广泛用于建筑、制造等领域。

Through the above steps, C-shaped steel can be successfully manufactured. This hot-rolled manufacturing method can ensure the strength and toughness of C-shaped steel, and is therefore widely used in fields such as construction and manufacturing.

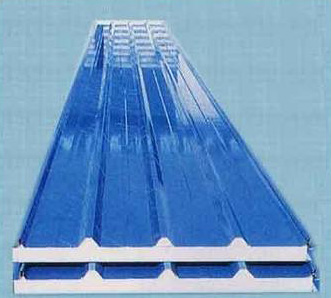

C型钢具有重量轻、强度高、具有良好的屈曲和抗压性能、易于加工和安装等优点。在建筑工程中,通常用于制作框架、屋面、墙板等,也常用于制作工业设备和机械组件。您对此有需求或者疑惑的话,欢迎来我们网站http://www.jnjgcg.com进行咨询!

C-shaped steel has the advantages of light weight, high strength, good buckling and compressive properties, and easy processing and installation. In construction engineering, it is usually used to make frames, roofs, wall panels, etc. It is also commonly used to make industrial equipment and mechanical components. If you have any needs or doubts about this, welcome to our website http://www.jnjgcg.com Consulting!

下一篇:选择聚氨酯戊烷夹芯板的好处 上一篇:彩钢瓦的使用要避开什么事项?

此文关键词: 济南C型钢厂

阅读/ Recommended reading

- 彩钢板生产工艺流程 2024-04-22

- 彩钢瓦是指什么?它的特点有哪些? 2024-04-18

- 有关复合板材的相关知识 2024-04-15

- 彩钢板储存需要注意哪些地方? 2024-04-11

济南c型钢是什么?有什么特点?

[2018-08-23]

型钢是一种常见的建筑材料,具有许多独特的特点。它由碳素钢制成,被广泛应用于各种建筑项目中。本文将详细介绍C型钢的定义以及其特点,以帮助读者更好地了解和使用这种重要的建材。Sect...