热门关键词:济南彩钢板 | 济南复合板 | 济南彩钢瓦 | 济南c型钢 | 济南钢结构 |

新闻中心

联系我们

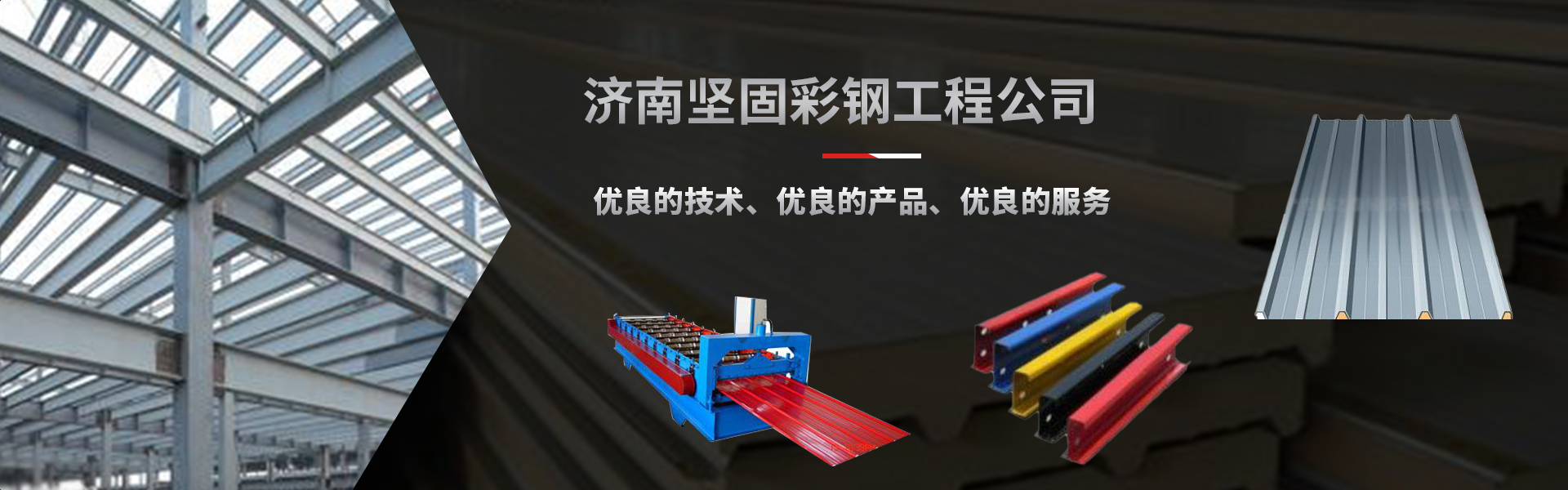

济南坚固彩钢工程公司

联系人:孙经理

电话:18963458998

地址:济南市工业北路81号北邻

冷轧c型钢的特性

来源:http://www.jnjgcg.com/ 日期:2023-06-27 发布人:

冷轧C形钢是C形钢生产过程中常见的C形钢类型。c型钢由C型钢成型机自动加工成型的。C型钢成型机根据给定的C型钢尺寸就可以自动完成C型钢的成型工艺。下面济南C型钢厂为您讲解更多产品信息:

Cold rolled C-shaped steel is a common type of C-shaped steel in the production process of C-shaped steel. C-shaped steel is automatically processed and formed by a C-shaped steel forming machine. The C-shaped steel forming machine can automatically complete the forming process of C-shaped steel based on the given C-shaped steel size. Below, Jinan C-beam Steel Factory will explain more product information to you:

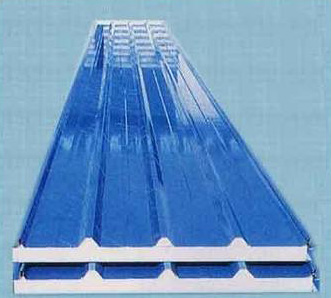

根据断面形状,型钢分简单断面型钢和复杂断面型钢。冷弯型钢用钢板或带钢在冷状态下弯曲成的各种断面形状的成品钢材。冷弯型钢是一种经济的截面轻型薄壁钢材,也称为钢制冷弯型材或冷弯型材。为了合理应用冷轧C形钢,我们来介绍一下冷轧C形钢的特点:

According to the shape of the section, steel sections are divided into simple section steel and complex section steel. Cold formed steel refers to finished steel products with various cross-sectional shapes formed by bending steel plates or strips in a cold state. Cold formed steel is an economical lightweight thin-walled steel, also known as steel cold formed profiles or cold formed profiles. In order to apply cold-rolled C-shaped steel reasonably, let's introduce the characteristics of cold-rolled C-shaped steel:

冷轧C型钢即是用热轧钢卷为原料,经酸洗去除氧化皮后型钢冷连轧,其成品为轧硬卷,由于连续冷变形引起的冷作硬化使轧硬卷的强度、硬度上升、韧塑指标下降,因此冲压性能将恶化,只能用于简单变形的零件。

Cold rolled C-section steel is a cold continuous rolling process that uses hot-rolled steel coils as raw materials and removes oxide scales through acid washing. The finished product is rolled hard coils. Due to the cold work hardening caused by continuous cold deformation, the strength and hardness of the rolled hard coils increase, and the toughness and plasticity index decrease. Therefore, the stamping performance will deteriorate and can only be used for parts with simple deformation.

轧硬卷可作为热镀锌厂的原料,因为热镀锌机组均设置有退火线。轧硬卷重一般在6-13.5吨,钢卷在常温下,对热轧酸洗卷型钢连续轧制,内径为610mm。

Rolling hard coils can be used as raw materials for hot-dip galvanizing plants, as hot-dip galvanizing units are equipped with annealing lines. The weight of the rolled hard coil is generally 6-13.5 tons, and the steel coil is continuously rolled at room temperature for hot-rolled pickling coil steel, with an inner diameter of 610mm.

产品特点:因为没有经过退火处理,其硬度很高(HRB大于90),机械加工性能极差,只能型钢简单的有方向性的小于90度的折弯加工(垂直于卷取方向)。

Product characteristics: Due to the lack of annealing treatment, its hardness is very high (HRB greater than 90), and its mechanical processing performance is extremely poor. It can only be easily bent and processed with a directional angle of less than 90 degrees (perpendicular to the coiling direction) for the section steel.

简单点儿来说,冷轧C型钢,是在热轧板卷的基础上加工轧制出来的,一般来讲是热轧---酸洗---冷轧C型钢这样的加工过程。

Simply put, cold-rolled C-beam steel is processed and rolled on the basis of hot-rolled plates and coils. Generally speaking, it is a processing process such as hot-rolling, pickling, and cold-rolled C-beam steel.

冷轧c型钢是在室温下由热轧板材制成的,尽管它们被称为冷轧c型钢,即使它们是在轧制过程中加热的。热轧冷轧c型钢由于连续冷变形,力学性能差,硬度过高。它必须退火,以恢复其机械性能,有没有退火所谓的轧制硬线圈。轧制线圈通常用于制造不需要弯曲或拉伸的产品。还有什么事儿就来我们网站http://www.jnjgcg.com咨询!

Cold-rolled C-beams are made from hot-rolled sheets at room temperature, although they are called cold-rolled C-beams, even if they are heated during the rolling process. Due to continuous cold deformation, the mechanical properties of hot-rolled and cold-rolled C-section steel are poor, and the hardness is too high. It must be annealed to restore its mechanical properties, without annealing the so-called rolled hard coil. Rolling coils are typically used to manufacture products that do not require bending or stretching. If there's anything else, come to our website http://www.jnjgcg.com consulting service

下一篇:几点购买复合板材时需要注意的问题 上一篇:用彩钢板搭建屋顶时有什么要求和技巧

此文关键词: 济南C型钢厂

阅读/ Recommended reading

- 彩钢板生产工艺流程 2024-04-22

- 彩钢瓦是指什么?它的特点有哪些? 2024-04-18

- 有关复合板材的相关知识 2024-04-15

- 彩钢板储存需要注意哪些地方? 2024-04-11

济南c型钢是什么?有什么特点?

[2018-08-23]

型钢是一种常见的建筑材料,具有许多独特的特点。它由碳素钢制成,被广泛应用于各种建筑项目中。本文将详细介绍C型钢的定义以及其特点,以帮助读者更好地了解和使用这种重要的建材。Sect...