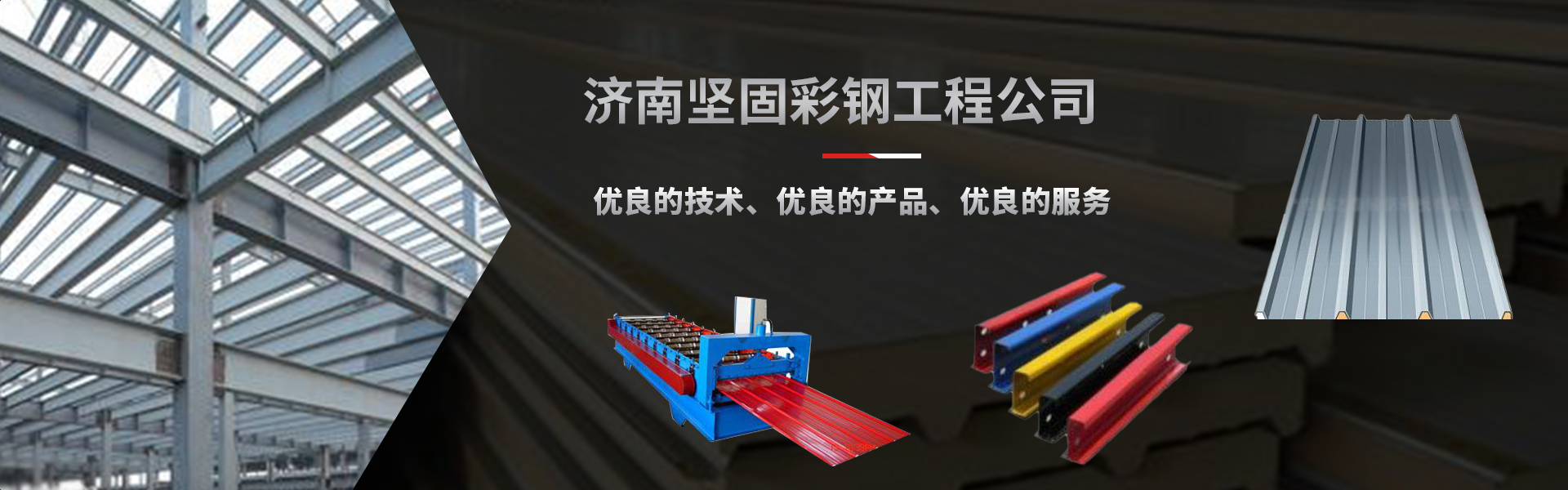

济南坚固彩钢工程公司

联系人:孙经理

电话:18963458998

地址:济南市工业北路81号北邻

济南C型钢厂:C型钢的制作工艺流程

C型钢的制作工艺流程

The production process of C-shaped steel

C型钢的制造过程包括以下步骤:

The manufacturing process of C-shaped steel includes the following steps:

1、放料:这是制造过程的开始,需要将原材料放入生产设备中。

1. Material release: This is the beginning of the manufacturing process, and raw materials need to be placed in the production equipment.

2、矫平:使用矫平机对原材料进行矫平,确保其平整度符合生产要求。

2. Leveling: Use a leveling machine to level the raw materials and ensure that their flatness meets production requirements.

3、成型:将矫平后的原材料送入成型机中,通过模具的挤压作用,使其初步形成C型钢的形状。

3. Forming: The flattened raw materials are fed into the forming machine, and through the squeezing effect of the mold, they are initially formed into the shape of C-shaped steel.

4、定型:在成型的基础上,通过定型机进一步调整C型钢的形状和尺寸,确保其精度和稳定性。

4. Shaping: On the basis of forming, the shape and size of C-shaped steel are further adjusted through a shaping machine to ensure its accuracy and stability.

5、矫直:对定型后的C型钢进行矫直处理,其内部应力和弯曲,使其达到规定的直线度。

5. Straightening: Straightening treatment is carried out on the shaped C-shaped steel to eliminate internal stress and bending, and achieve the specified straightness.

6、测长:使用测量设备对C型钢的长度进行测量,确保其长度符合生产要求。

6. Length measurement: Use measuring equipment to measure the length of C-shaped steel, ensuring that its length meets production requirements.

7、冲拉筋圆孔:在C型钢上冲制拉筋圆孔,以满足后续安装和连接的需要。

7. Punching round holes for tie bars: Punch round holes for tie bars on C-shaped steel to meet the needs of subsequent installation and connection.

8、冲椭圆连接孔:在C型钢上冲制椭圆连接孔,用于与其他部件的连接。

8. Punching elliptical connection holes: Punching elliptical connection holes on C-shaped steel for connection with other components.

9、成型切断:,将C型钢按照规定的长度进行切断,完成整个制造过程。

9. Forming and cutting: Finally, cut the C-shaped steel according to the specified length to complete the entire manufacturing process.

需要注意的是,在生产过程中,还需要使用一些辅助材料,如焊接材料、防锈涂料等,以确保C型钢的质量和耐腐蚀性。此外,还需要对生产过程中的各个环节进行严格控制,确保产品质量和生产效率。

It should be noted that during the production process, some auxiliary materials such as welding materials, rust proof coatings, etc. need to be used to ensure the quality and corrosion resistance of C-shaped steel. In addition, it is necessary to strictly control each link in the production process to ensure product quality and production efficiency.

C型钢的制造过程是一个复杂而精细的过程,需要的生产设备和技术人员来保证产品的质量和性能。

The manufacturing process of C-shaped steel is a complex and delicate process that requires professional production equipment and technical personnel to ensure the quality and performance of the product.

本文内容来自:济南C型钢厂 如果您想了解更多关于本行业知识请认准: http://www.jnjgcg.com,欢迎您的到来!

The content of this article comes from Jinan C-shaped Steel Plant. If you want to learn more about this industry, please take note: http://www.jnjgcg.com Welcome to come!

阅读/ Recommended reading

- 济南彩钢板:YX50-410-820-0.5mm厚屋面彩钢板规格及一平米有多重 2024-07-19

- 注重消防,防范彩钢板火灾 2024-07-19

- 彩钢房:彩钢皮除锈小技巧你知晓吗? 2024-07-06

- c型钢的特点和基本知识介绍 2024-06-13

彩钢岩棉复合板的安装方法如下: The installation method of color steel rock wool composite board is as...